Polypropylene is the ideal material for the manufacturing of our plastic cups. It is the best material to be reused and recycled because it is free of chlorine. It does not contain bisphenol A.

Lightweight cups, with minimum thickness needed, stackable and elastic to prevent breakage.

Plastic cups with a rounded finish and well-polished. The rough surface is for the purpose of improving the use.

We customize the cups with the best current techniques. From silkscreen ink to IML four-colour photographic printing.

With the improvement of the register brands and the new printing techniques, the customizable surface of the cup has been increased. With techniques like the IML the printable surface is already 100%.

We follow the regulations of food use in EC regulation 1935/2004 of 2004.

Our printed cups resist more than 90ºC, which is higher than most dishwashers on the market. This is the temperature necessary for the elimination of bacteria.

We have a washing service, with certification of results for food use.

For large quantities there is the possibility of being able to create a clean mold to reinforce the own brand on the base of the reusable cup.

"The best reusable cup? With good design and high-quality printing"

"The best reusable cup? With good design and high-quality printing"

Silk screening is a stamping process. It is carried out by means of the stenrail method, through a porous tissue (screen), through which a squeegee passes the ink or paint.

We have specific machines that allow us to print the 360º of the surface of the reusable cup. In addition, you can register multiple prints (colors).

The print can be one or more inks. From three colors we recommend using other techniques such as four-colour process, the cost of which is lower.

With silk screening you can stamp other products such as personalised plates, reusable dishes, bowls or reusable plastic pitchers. Some, however, only allow one ink.

The range used is PANTONE. In the workshop, we have inks in stock that we offer you at the best price, but you can use any other corporate colour.

The design of the cup printing is the responsibility of the customer. It is necessary that they are ready preferably in vector (.ai) and following our normative of printing.

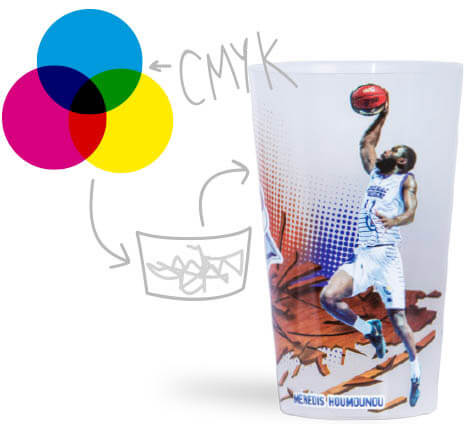

The term "mold labeling" comes directly from the technique: a pre-printed label of polypropylene is in the same mold for making the rigid plastic cup. Next, the molten polypropylene is injected, which fuses with the label and takes the form of the plastic cup.

The result: the label and the cup become a unique product.

The printing of the polypropylene label is done flat with the same techniques and machines as the standard four-colour paper. The quality and the possibilities, however, are the same as one can do on paper.

This impression is mainly made with transparent and/or translucent polypropylene. In the same way, the base of the polypropylene of the label is also transparent. To improve the saturation and opacity of the prints, it is customary to apply a white ink base above the printing area of the label.

We can play with opacities and transparencies to improve in design functionality the printing of recyclable plastic cup. It should be preferably ready in vector, in Illustrator (.ai), in CMYK and the indentation. For more information, see our printing standards.